Intelligent Manufacturing For the Future

Regarding the frontiers of manufacturing, MSE (Mechanical Science & Engineering) has shown itself a key player in supporting an innovation-driven China, and strives for a world-leading innovation engine in intelligent manufacturing for the future.

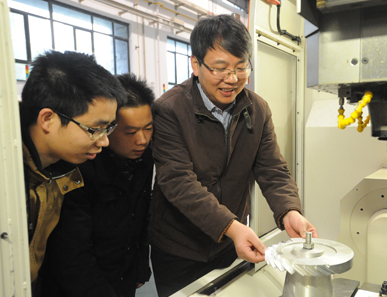

Complex Surface Machining:to Meet Challenges in Aero Engine

Manufacturing of engine components faces great challenges, which are directly driven by exploding global traffic growth and CO2 emission reduction requirements involved with the high-performance engines applied in civil aerospace, marine, and energy. MSE is hosting one of the leading groups in the world for exploring of the fundamentals of machining process, especially in machining of complex surfaces like aero engine components. The group demonstrates that the classical mechanics, modern differential geometry and robotics can be employed to handle the difficulties in the physical simulations of machining process. The innovative work has consequently advanced the understanding of machining process, improved the machining quality, achieved maximum productivity, and brought in great economic benefits.

High Power Laser Processing: for Seamless Structuring

High power laser processing is widely used in many fields, such as aviation, aerospace, marine, automobile and so forth. MSE has hosted a series of fundamental researches and engineering developments in this field, such as advanced processing (welding, cutting and weakening), seamless 3D tracking and intelligent compensation control, high-end digital equipment, etc. Through experiments, simulations and tests, the complex phenomenon of high power laser processing has been deeply explored including weld pool, plasma, droplet transfer, welding deformation and residual stress of the laser processing. Leading the laser processing research over the last decade, the HUST team has strongly supported the rapid advance of Made in China.

Intelligent Robotics: for Healthcare of the Disabled

Disability is an unfortunate but realistic part of living condition in our society. Large number of the disabled and increasing ageing have become serious social problems and consequently restricted the economic development. MSE has devoted years of research to exploring the fundamentals of human motor control and proposed novel concepts on the design and control of biomechatronics devices. The interdisciplinary methods have been applied in developing mind-controlled robotics for functional repair and functional alternative of the disabled. Our advanced robot is capable of reproducing diverse human motor functions and interacting with the user under neural commands, which promotes the disabled closer to the real world.

Flexible Electronics: the Next Ubiquitous Platform

An emerging field in electronics focuses on large-area, flexible or stretchable, conformable applications. Flexible electronics provide the pervading technologies in health and environment monitoring, flexible displays, human–machine interactivity, wearable electronics, bio-integrated electronics, energy storage and generation, and communication and wireless networks. MSE has launched a series of fundamental research and engineering works for flexible electronics manufacturing, including the design of materials and devices, low-temperature film deposition, multi-scale patterning, large-area debonding, and advanced integration and packaging. Multifunctional and flexible design, and high-throughput and low-temperature manufacturing are desired attributes for the next-generation flexible electronics.

Advanced micro/nano manufacturing technologies: for future energy and sensing

Micro/nano manufacturing technologies are one of the hot focuses for international research topics and promising for a wide variety of applications such as aerospace, microelectronics, health and environmental area. MSE has been undergoing a series of nano-manufacturing, cross-scale micro/nano manufacturing methods and processes based on silicon, carbon, metal/oxides materials etc, and developed competitive high-performance MEMS/NEMS, microbatteries, supercapacitors and sensors. We aim to explore the innovative scalable fabrication methods in micro/nano area, and promote their novel applications toward future energy conversion/storage and sensing through multi-disciplining cooperation.

Information Sensing and Precision Instruments:Eyes for Intelligent Manufacturing

Information sensing and precision measurement & control system is basis for intelligent manufacturing, because it promotes informatization and automation for high precision, high effective and stable manufacturing. In MSE for high level manufacturing objective, many researches on precision measurement principles, methods and technology have been carried out based on optics, electricity, magnetics, acoustics and their recombination, and many precision instruments and measurement systems have been developed for equipment accuracy inspection, product quality monitoring and process analysis. For intelligent manufacturing, precision measurement & control system for on-line testing, equipment status information acquisition, analysis and dynamic compensation and active control technology have also investigated and applied. With the development of internet and wireless communication technology, distributed manufacturing information sensing system and network based real-time control technology will be an important field MSE will take for intelligent manufacturing.