On April 6th, the latest research results titled “Programmable, High-resolution Printing of Spatially Graded Perovskites for Multispectral Photodetectors” were published online in the prestigious international journal “Advanced Materials”. Our school's State Key Laboratory of Intelligent Manufacturing Equipment and Technology is the first completion unit of the paper. Associate Professor Duan Yongqing, master students Yu Rui and Zhang Hanyuan from our institute are the co-first authors of this paper, while Professor Huang Yong'an and Professor Yin Zhouping are the co-corresponding authors. Our doctoral student Yang Weili and master student Xie Wenshuo also participated in this research.

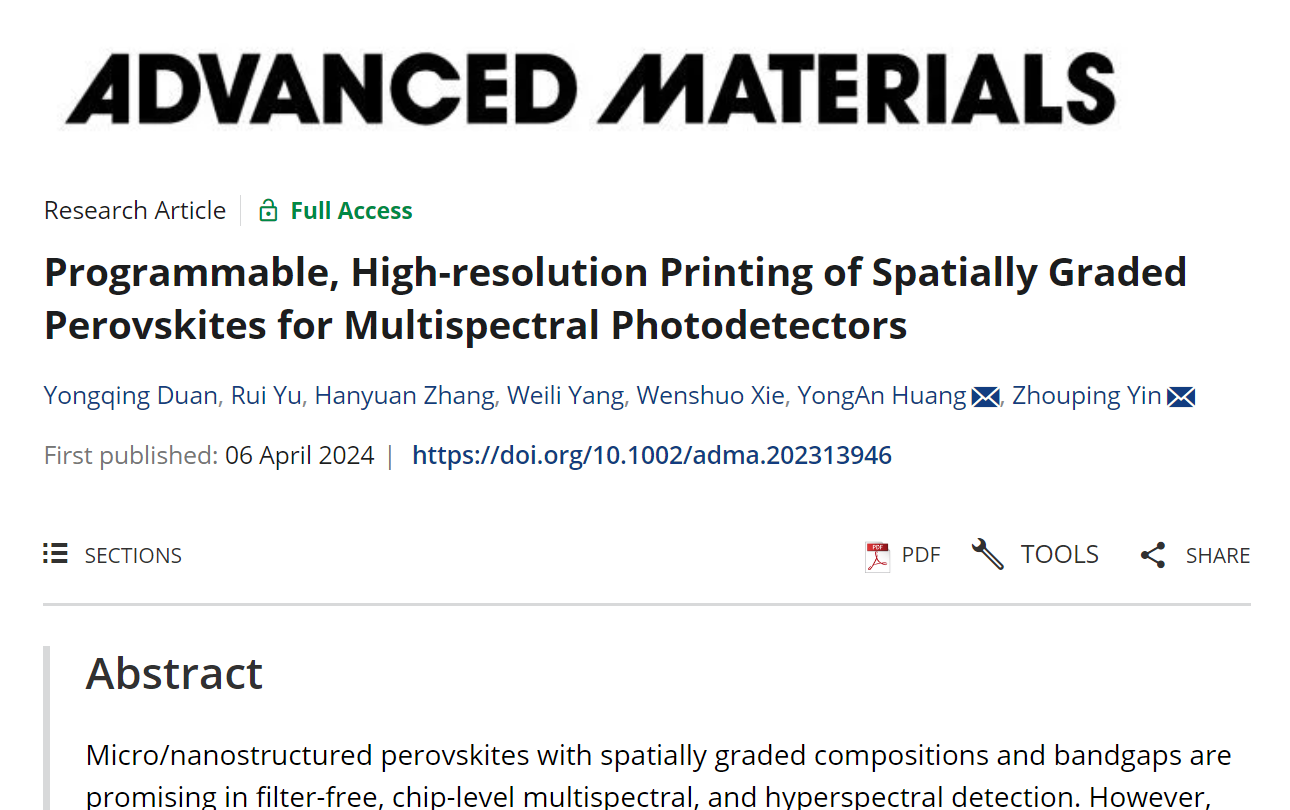

The performance and functionality of micro-nano gradient structures gradually change with spatial direction, holding significant application prospects in fields such as miniaturized spectrometers and full-color imaging. However, the direct deposition of materials with gradient changes to form arbitrary micro/nano patterns or large-scale arrays still faces significant challenges. To address this, the team has proposed a novel Mixed Electrohydrodynamic Printing (M-ePrinting) technology for the first time. This technology employs a single nozzle with multiple channels to simultaneously spray multiple solutions, and by controlling the driving voltage on each channel, it controls the composition of the mixed droplets, achieving in-situ mixing and spraying of gradient micro-nano structures. By optimizing printing parameters, the characteristic size of gradient patterns can be reduced to as small as 1 μm, which is the highest resolution achievable for gradient structure preparation via printing known to date.

Figure 1. Basic process principles and application of M-ePrinting.

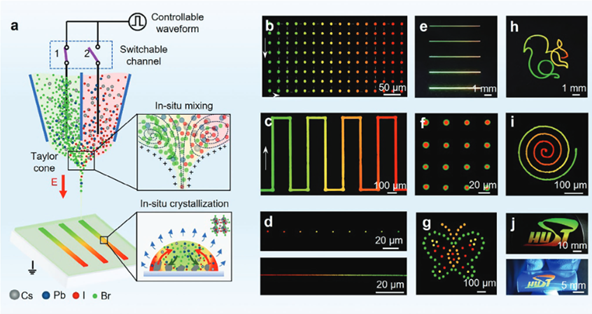

For achieving digitally printed perovskite patterns/arrays with controllable material composition, the influence of channel switching and waveform variation on printing results was studied, and the change of Taylor cone and the proportion change of solution mixture during printing process were simulated.

Figure 2. Research on droplet composition control of M-ePrinting

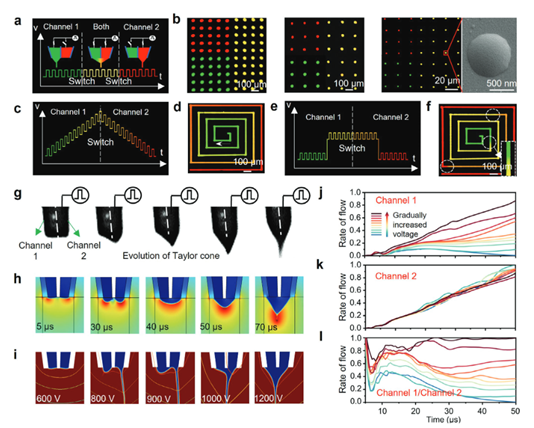

To obtain perovskite films with higher quality and fewer defects, the drying and annealing process after printing was studied. It was found experimentally that by controlling the mixing time of multi-component droplets on the substrate, incompletely mixed concentric dots or completely mixed uniform dots can be achieved. These novel and controllable gradient dot arrays may have important applications in high-density, tunable-bandgap devices.

Figure 3. Post-treatment of printed perovskite films.

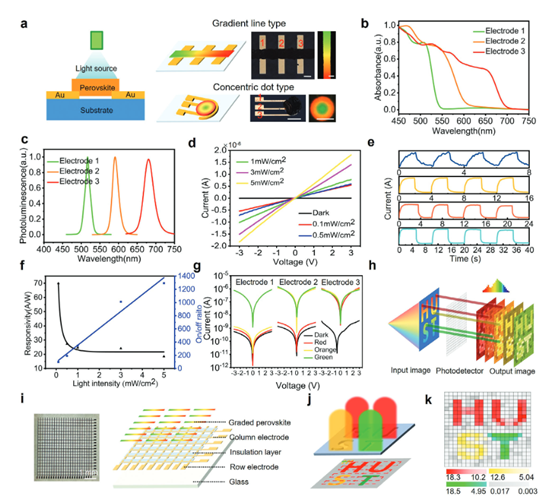

Based on the printed gradient perovskite films, multispectral photodetectors were fabricated. The fabricated devices exhibit advantages such as high on/off ratio (1.29×103), low response time (trise = 100 ms, tfall = 60.1 ms), and high sensitivity (R = 69.88 A/W, D* = 3.27×1015 Jones), as well as color recognition and color image reconstruction capabilities.

Figure 4. Performance of graded perovskite-based photodetectors.

This work proposes a novel mixed printing method and achieves for the first time high-resolution gradient patterns with a feature size of 1 μm, holding tremendous potential in fields such as miniaturized spectrometers and hyperspectral imaging. Moreover, this technology can be extended to more channels and more types of inks, enabling high-resolution, high-efficiency manufacturing of complex component gradient micro-nano patterns. It provides a competitive method for miniaturized spectrometers and artificial vision systems and opens up new avenues for the digital manufacturing of component-programmable structures.

The above research work was supported by the National Natural Science Foundation of China.

Original link: https://onlinelibrary.wiley.com/doi/10.1002/adma.202313946?af=R