On June 2nd, Nature Communications published the paper “A Powder-metallurgy-based Strategy Toward Three-dimensional Graphene-like Network for Reinforcing Copper Matrix Composites”, which was the latest research findings of Prof. Zhu Fulong’s team of MSE and Prof. He Chunnian’s team of Tianjin University on graphene- metallic composites. Dr. Zhang Xiang of Tianjin University was the first author, graduate student Xu Yixin and doctoral student Wang Miaocao of HUST were the second and third authors, while Prof. Zhu Fulong and Prof. He Chunnian were the corresponding authors. Assistant Professor Lin Dong of Kansas State University also gave some advice on the paper.

Owing to its unique and fascinating properties such as superior strength and elastic modulus, giant electron mobility, high thermal conductivity, excellent mechanical flexibility, and large specific surface area, graphene (Gr), a two-dimensional and conjugated honeycomb carbon structure, has been extensively exploited to integrate in ceramic, polymer or metallic matrices for achieving novel composites with outstanding mechanical, electrical, and/or thermal properties. However, a huge challenge still lies in taking advantage of the extraordinary properties of 2D graphene in the composites because of the easy stacking and the resultant agglomeration problems of graphene nanosheets (GNSs) as well as high contact resistance between GNSs in the matrixes, thereby resulting in only moderate enhancement efficiency in the mechanical, electrical, and/or thermal properties of the graphene-based composites. The researchers’ approach offered a general way for manufacturing metal matrix composites with high overall performance. Graphene networks have been used to reinforce polymer and ceramic composites, but connecting graphene into a three dimensional network in a metal matrix is challenging. And the researchers used a powder-metallurgy-based strategy to construct a three-dimensional graphene network reinforced copper matrix composite.

Both experimental and theoretical calculations showed that thermal stress played an important role in the formation of graphene sheet welding and network configuration. More importantly, it was demonstrated for the first time that the network configuration could effectively increase the interfacial shear stress between graphene and copper (more than two times higher than that of two-dimensional graphene / copper), thus promoting the mechanism of load transfer strengthening. At the same time, the results showed that the continuous graphene network in copper matrix could not only effectively improve the mechanical properties (strength and toughness) of the composites, but also improved the physical properties of electrical and thermal conductivity. In addition, the preparation method and calculation model in this paper could be extended to the three-dimensional network composed of other two-dimensional structural elements (such as hexagonal boron nitride, transition metal two-dimensional sulfides and oxides) and the preparation of metal matrix composites (copper, magnesium, aluminum, titanium, etc.), which was expected to promote the structural and functional application of such composites.

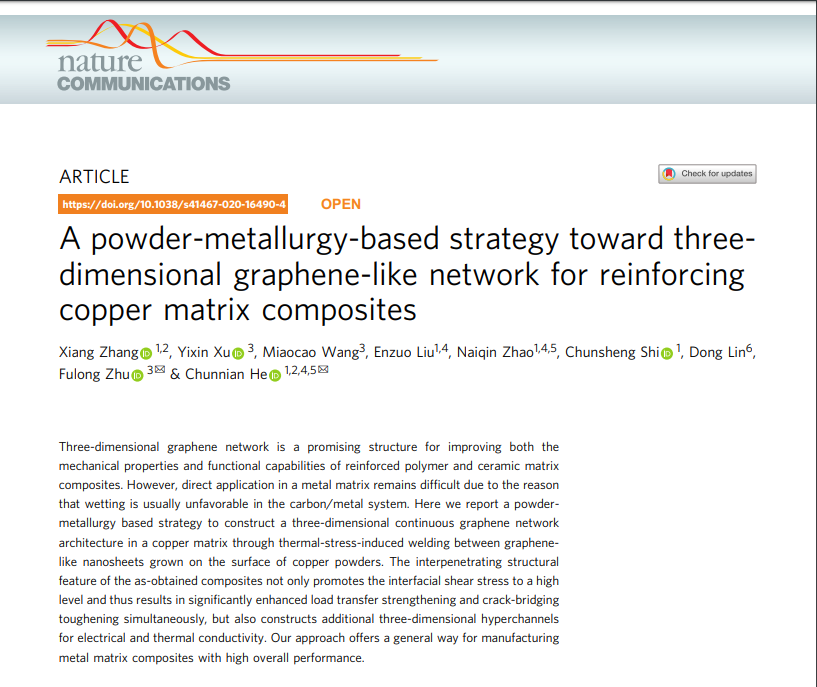

Figure 1 Preparation method of the three-dimensional graphene-like network copper(3D-GLNN/Cu)

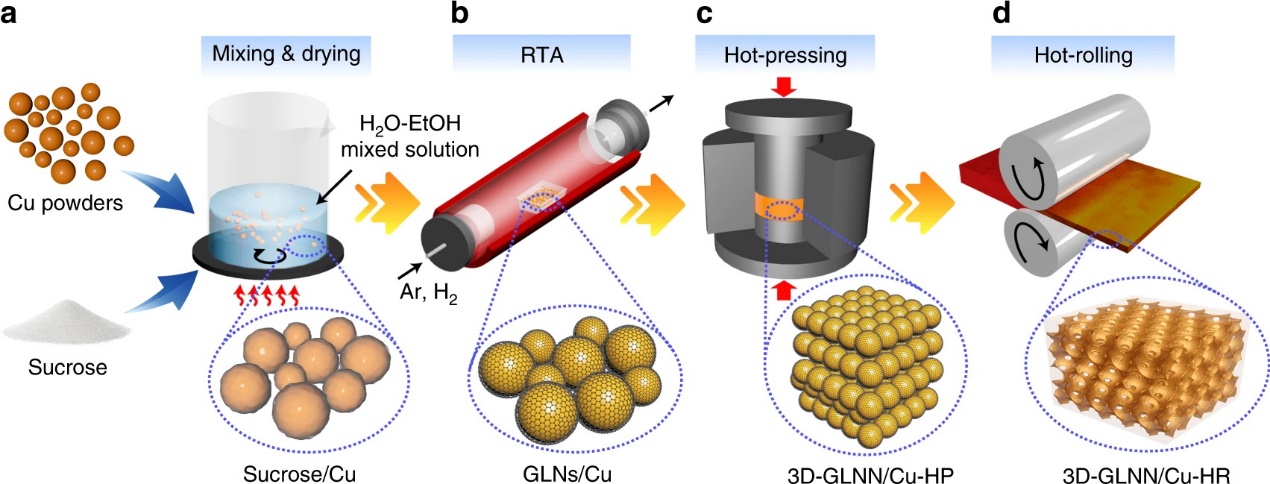

Figure 2 Structure evolution of 3D-GLNN/Cu during thermal pressing

Figure 3 Molecular dynamics calculation of graphene-like welding mechanism

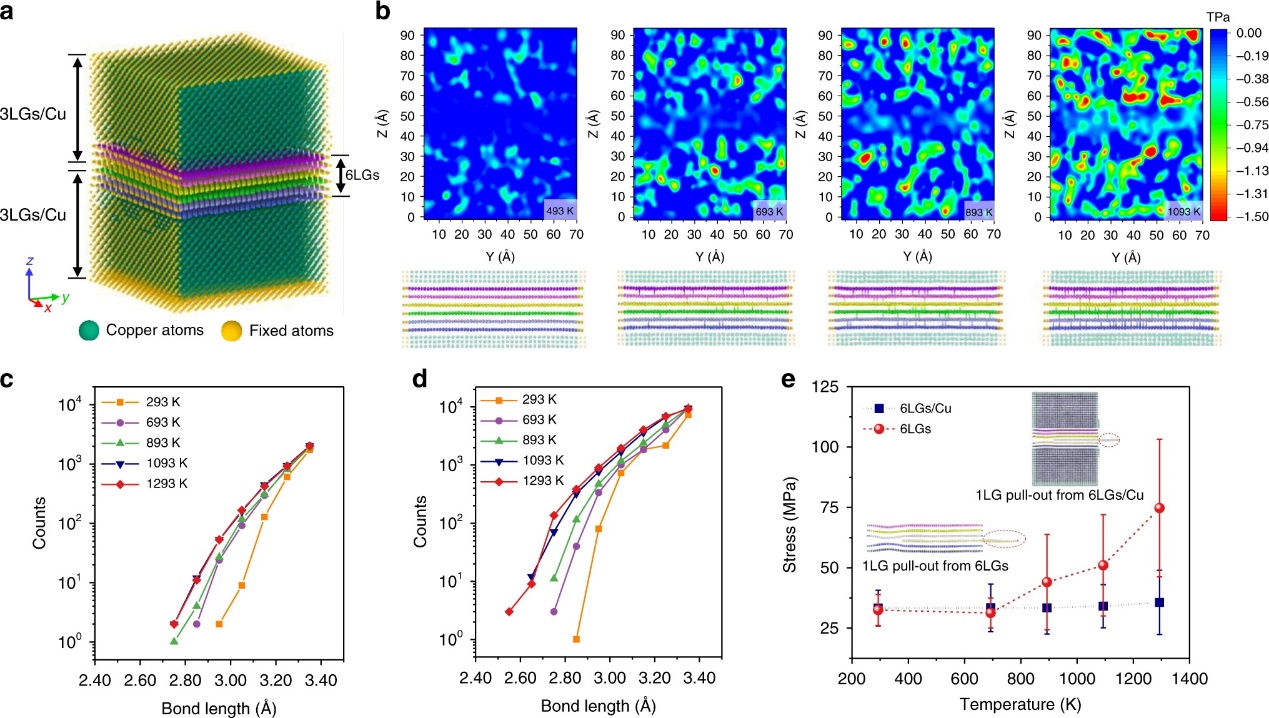

Figure 4 Contrastive analysis of three-dimensional and two-dimensional graphene-copper in mechanical properties calculation and experiment

The research was financially supported by the National Natural Science Foundation of China (Grant No. 51771130, 51531004, 51675211, and 51422104)

Link of the paper: https://www.nature.com/articles/s41467-020-16490-4