On April 8, the project team "Research on highly efficient nanosecond laser cutting technology for photovoltaic calendered glass", composed of MSE juniors, published their latest research achievement "Error analysis in 532nm nanosecond laser cutting of solar glass" in Optik (International Journal for Light and Electron Optics), under the guidance of Prof. Huang Yu and Associate Prof. Rong Youmin of the State Engineering Research Center of Digital Manufacturing and Equipment. This is the second time that the team has published an academic paper in the journal (the first one was published in December 2020). Dong Haoyu, a junior in class 1801, was leader of the project team and the first author of the two papers. Associate Prof. Rong Youmin was the corresponding author, and Prof. Huang Yu the second. It is worth mentioning that this is the first time in HUST that junior undergraduates completed independently the project research work under the guidance of the tutor, and published two SCI papers as first authors.

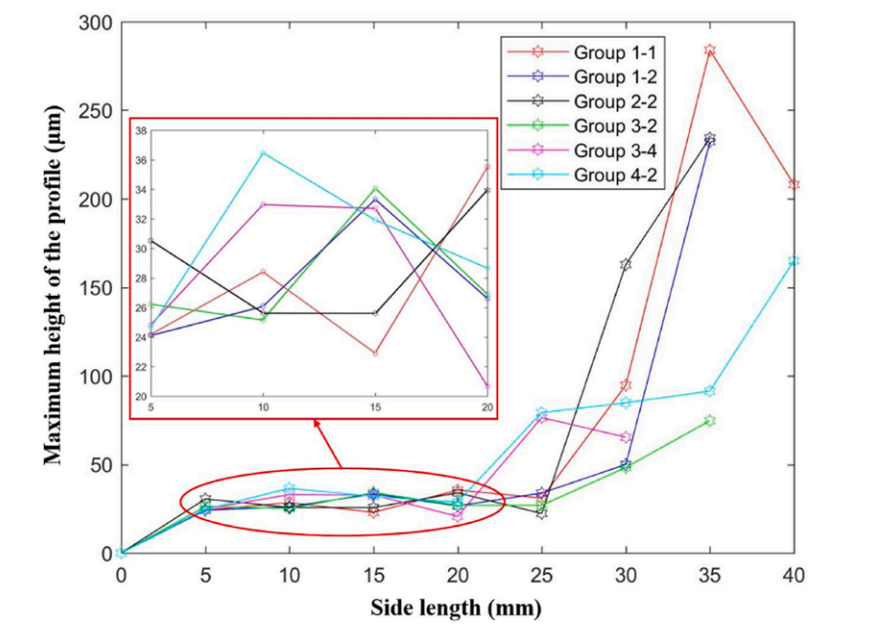

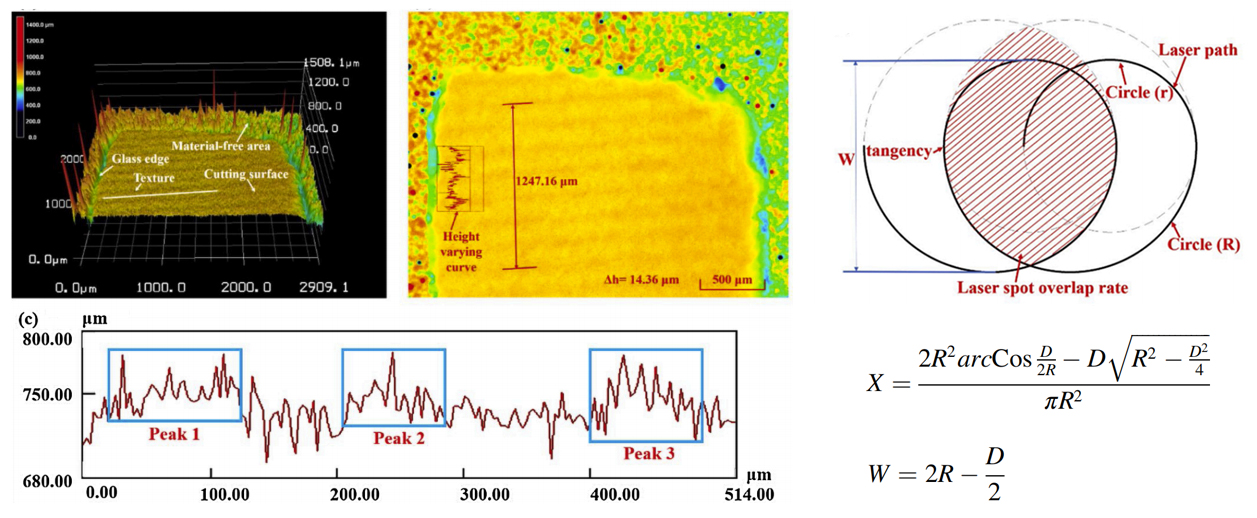

Ever since a year ago, the team has carried out research on the laser cutting process and mechanism of hard and brittle glass. Hard brittle glass is widely used in aerospace, photovoltaic, automotive, high-end construction and other fields. In recent years, the research on the laser cutting process and quality assurance technology of hard brittle glass has been a hot and also difficult topic. The team studied the formation mechanism of workpiece burr defects and the exponential growth model of surface roughness value with laser offset distance, and formed the optimization method for process parameters with low edge collapse constraint, which reduced the surface roughness of workpiece from 7 μ M to 5 μ. At the same time, the team studied the formation mechanism of the surface texture, establishing the analytical model of the width and overlap rate of the helix on the width and height of the cutting texture, and thus realized the accurate prediction of the texture shape. The results will play an important part in forming the cutting technology of stable laser hard and brittle glass.

Fig. 1 cutting quality changed with different offset distance

Fig. 2 texture on the glass cutting surface and its analytical model

In addition to the support of National Natural Science Foundation of China, Key Research and Development Plan of Hubei Province, the project team also received the fund support of Undergraduate Research Opportunities Program (UROP). UROP Program Fund is a scientific research and innovation fund especially set for all undergraduates of HUST, which was jointly established in 2015 by MSE, the National Engineering Practice Education Center of Wuhan Wuzhong Casting & Forging Co., Ltd. and HUST, and Hubei Provincial Demonstration Base for Practical Training of college students. The Program has supported over 40 projects, with more than 200 undergraduate students and 50 MSE teachers participating in the project design and guidance, which greatly improved the students’ ability to engage in scientific research while achieving related academic achievements. This project is an excellent example of undergraduate students participating in scientific research.

Link to the paper:

https://www.sciencedirect.com/science/article/pii/S0030402621001832?via%3Dihub

https://www.sciencedirect.com/science/article/pii/S0030402620314546?via%3Dihub